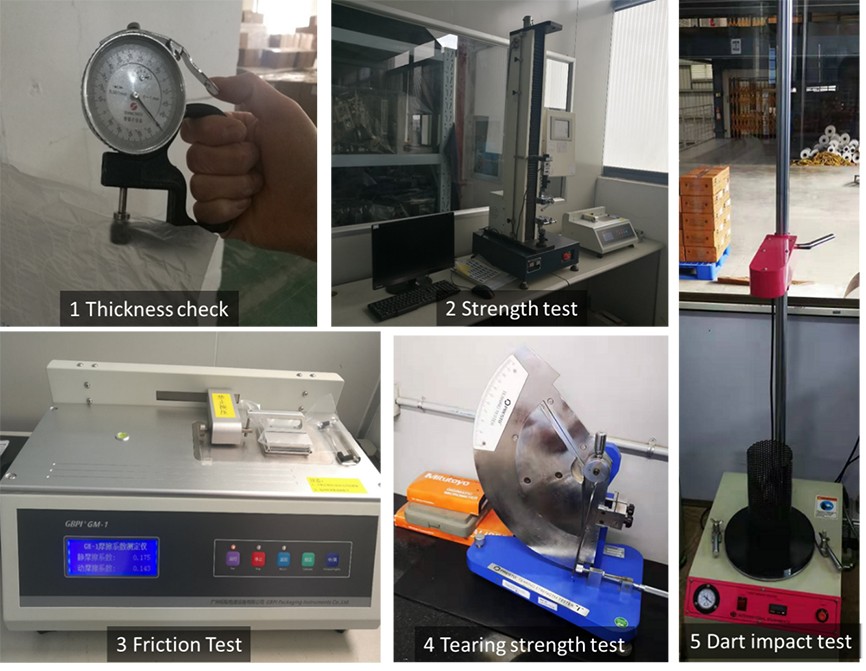

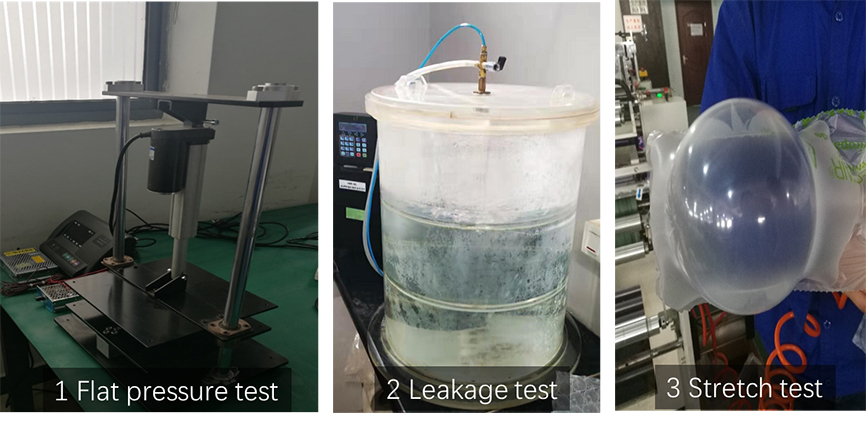

Every batch of film material will go through a series of inspections before being allowed into production.

Even the carton and cores will be inspected and recorded.

During production, all processes are clearly guided with CBA(Current Best Approach) and quality standard. The key dimension is checked with a sensor or vision system.

Every 5 rolls, QA will test the film to check the converting result to avoid any leakage possibility. Test data will be recorded and kept onfile.

In addition , the 1st 5 piece of every roll will be kept as sample to be kept for 2 years.

1.Tracking system

Every roll of our film will have identification number. With this number LockedAir be able to check the following information:

Production information including date, shift, machine, operator, etc.

Material batch and quality record

Sample pieces of this roll

On-line production data from sensor or vision system.

2.Supervisor- Group leader- QA 3 Level Quality Audit System

Supervisor quality responsibilities:

develop product quality standards, write variovs inspection reports, experimental procedures

responsible for the investigation and handling of customer complaints and corrective measures tracking verification

responsible for the production process of abnormal quality analysis and improvement effect tracking

responsible for staff quality training

responsible for the introduction of new products in the early quality planning, review and confirmation

responsible for the implementation and implementation of the quality assurance system

Group leader quality responsibilities:

responsible for the implementation and implementation of product quality standards

responsible for the implementation of the quality assurance

has the responsibility of supervision over the product quality of the team

responsible for the team's quality awareness publicity

QA quality responsibilities:

the implementation of product quality standards and procedures

responsible for raw material inspection

responsible for product inspection

responsible for the inspection of the production process

responsible for the identification, isolation and registration of non-performing products