-Easy to load, simple to use.

-Sturdy shaped paper bubbles, better protection.

-Jam free design, lower down time loss.

Metric System

| Machine Spec. | Paper Option | ||||||

| Voltage | 100-240V | Model No. | Mat. | Basis Weight (gsm) | Length(m) | Width(mm) | CTN/Pallet |

| Power | 350W | MPS-80-500 | Stretch | 80 | 500 | 500 | 94 |

| Weight | 28KG | MPS-80-300 | Stretch | 80 | 500 | 300 | 96 |

| Max output speed | 12m/min | ||||||

Machine Size (mm) | 716x400x289 | ||||||

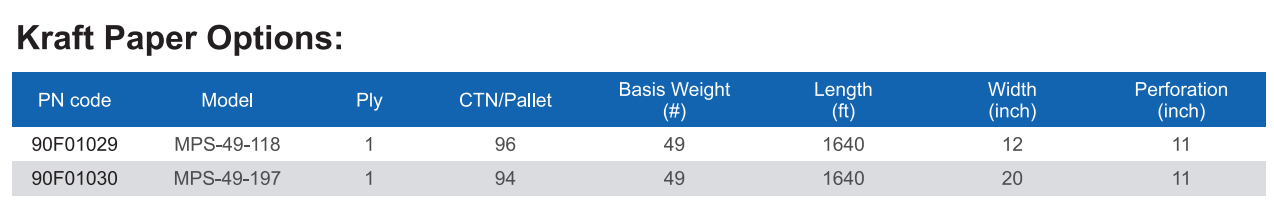

Imperial System

| Machine Spec. | Paper Option | ||||||

| Voltage | 100-240V | Model No. | Mat. | Basis Weight | Length(feet) | Width(inch) | CTN/Pallet |

| Power | 350W | MPS-80-500 | Stretch | 49# | 1640 | 19.7 | 94 |

| Weight | 62LBS | MPS-80-300 | Stretch | 49# | 1640 | 11.8 | 96 |

| Max output speed | 39.4feet/min | ||||||

| Machine Size (inch) | 15X11X12 | ||||||

1. Flexible and Economic:

On-Demand Packaging: Cost-effective paper bubble machine designed to produce recyclable paper bubbles precisely when needed.

Eco-Friendly Packaging: Utilizes recyclable paper bubbles for cushioning protection, reducing environmental impact.

Space-Saving: Compact design with a small footprint, making the bubble paper making machine suitable for placement on any table.

2. Ease of Use:

Effortless Assembly: This paper packaging machine is easy to assemble and set up, ensuring quick deployment.

Intuitive Interface: User-friendly LCD touchscreen for seamless operation.

Simplified Process: Simple procedures for production, wrapping, and cutting, enhancing overall usability.

3. Durable and Reliable:

Long-Life Blade Design: Engineered with a durable blade for extended lifespan, minimizing maintenance requirements.

Versatile Operation: Manual and auto modes with adjustable speeds cater to specific packaging needs.

Precision Cuts: Ensures sharp and clean cuts for a professional finish and optimal protection.

Invest in our Paper Bubble Wrap Machine for a versatile, user-friendly, and environmentally conscious packaging solution. Experience the flexibility of on-demand packaging, coupled with the durability and reliability needed for efficient and sustainable operations.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Paper Bubble Wrap Machine is designed to convert flat kraft paper into unique paper bubbles.

The bubble paper making machine is used for packaging fragile items. So how is it different from traditional bubble wrap?

1. Easier to use

LockedAir paper bubble machine can produce paper bubbles on demand without the need to regulate temperature and blowing volumn like traditional bubble machines, and with less noise.

2. Easier to maintain

Traditional bubble machines require regular replacement of heating tape and blades, paper bubble wrap machine blades are designed to be durable and usually do not require replacement of wear parts.

3. Better out-of-the-box experience

The paper bubble machine produces paper bubbles converted from recyclable kraft paper. The bubble paper making machine can be recycled many times and is more green. Packing products with Inbubble paper bubbles is more environmentally friendly and the customer's unboxing experience is better!

User-Friendly Operation: Our paper bubble machine is designed with ease of use in mind. From straightforward assembly to a user-friendly interface, the LockedAir experience is built for efficiency, ensuring a seamless operation for every user. From straightforward assembly to a user-friendly interface, the LockedAir experience is built for efficiency, ensuring a seamless operation for every user.

Space-Saving Design: With a small footprint, our paper bubble wrap machine can be conveniently placed on any table, maximizing space efficiency in your workspace.

Fast delivery and after-sales response: We set up companies and warehouses in the United States, Australia and Europe Germany, and have professional engineers to provide door-to-door service, whether it is a purchase or repair can provide a quick response.

More competitive price: We have our own bubble paper making machine factory to control the whole process from raw material to production. Not only can we ensure the quality, but also bring more accurate and competitive price.

Our paper bubble machine is designed with ease of use in mind. From straightforward assembly to a user-friendly interface, the LockedAir experience is built for efficiency, ensuring a seamless operation for every user. From straightforward assembly to a user-friendly interface, the LockedAir experience is built for efficiency, ensuring a seamless operation for every user.

With a small footprint, our paper bubble wrap machine can be conveniently placed on any table, maximizing space efficiency in your workspace.

We set up companies and warehouses in the United States, Australia and Europe Germany, and have professional engineers to provide door-to-door service, whether it is a purchase or repair can provide a quick response.

We have our own bubble paper making machine factory to control the whole process from raw material to production. Not only can we ensure the quality, but also bring more accurate and competitive price.

Provide one-year warranty service, as well as fast response online after-sales remote guidance and local after-sales team service.

We have independent warehouses in the USA, Germany and Australia as well as distributors in 52 countries worldwide. We will arrange shipment from your nearest warehouse.

Our after-sales team will contact you and have an after-sales engineer in the corresponding region to repair the parts or replace the machine.

We will choose the nearest warehouse as soon as possible for you to ship, do not need you to wait too long!

We offer express delivery by sea and air, and home delivery in our warehouse area.

There is no requirement for MOQ, usually customers will choose to match the kraft paper so that the shipping cost will be cheaper.